Trilobio

I worked for Trilobio as part of the Harvey Mudd College Clinic Program. Trilobio seeks to revolutionize synthetic biology by creating affordable and modular robots with a biologist-friendly programming interface.

Our team designed a 96-channel pipette attachment for Trilobio's robotic arm. Our first-of-a-kind design creates airtight seals between all 96 pipette tips and the pipette without loading the robotic arm. To create the seals, our design utilizes inflatable sleeves that expand after they are inserted into the pipette tips.

I designed and fabricated prototypes using FDM, SLA, and SLS 3D printers and CNC lathes and mills. I also worked with metals, hard plastics, and flexible materials to experiment with creating airtight seals in small volumes.

We demonstrated our novel sealing method by creating a fully functioning 8-channel prototype that successfully integrated with Trilobio's robot, created airtight seals, and aspirated fluid.

Working on this project has taught me a lot about robotic systems, design for manufacture, flexible materials, rubber/silicone, motors and actuators, and air and water-tight interfaces.

Click here for a deeper dive into the project

8 Channel Prototype Creating Seals and Aspirating Fluids

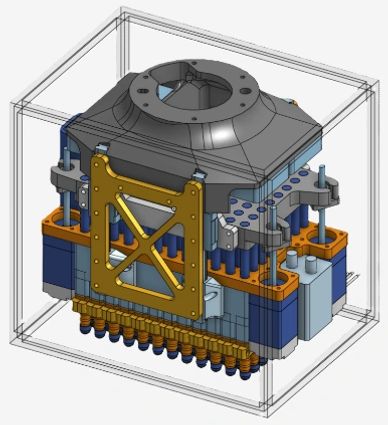

96 Channel Pipette Design. Box Shows Maximum Allowable Dimensions

Cross Section of Uninflated Pipette (Left) vs Inflated Pipette (Right)

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.